Electronic Industry Effluent

The electronic industry effluent was characterized to identify the microbial population. Regeneration studies suggested that SP- biohydrogel could be reused upto 5 cycles and could serve as a cost effective alternative for the recovery of.

Pin By Industrial Wastewater On Electro Oxidaiton Wastewater Treatment Water Treatment Wastewater

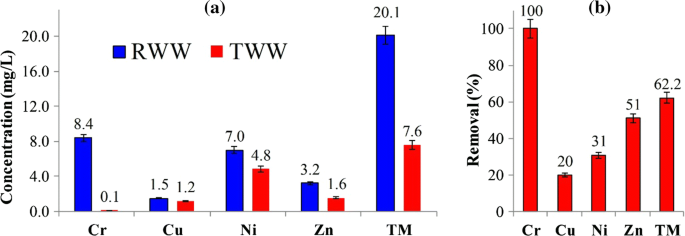

Minimum Inhibitory Concentration MIC of the strain toward cadmium and lead was found to be 200 mg L -1 and 400 mg L -1 respectively while it could tolerate zinc up to 250 mg L -1 and chromium up to 150 mg L -1.

Electronic industry effluent. Batch and column studies The present investigation attempts to recover the ceriumIII ions from. Taxonomic identification of this microbial community would be interesting as no information on the microbial diversity from electronic industry effluent is available till date. The objective of this study is to study the feasibility of applying reverse osmosis RO membrane separation to reduc.

The electronics industry especially meaning consumer electronics emerged in the 20th century and has now become a global industry worth billions of dollars. Wastewater 60 RO is suitable to the treatment of the fluorides present in the effluents of the electronics industry. Treatment of electronics industry effluent using low-cost and commercial adsorbents.

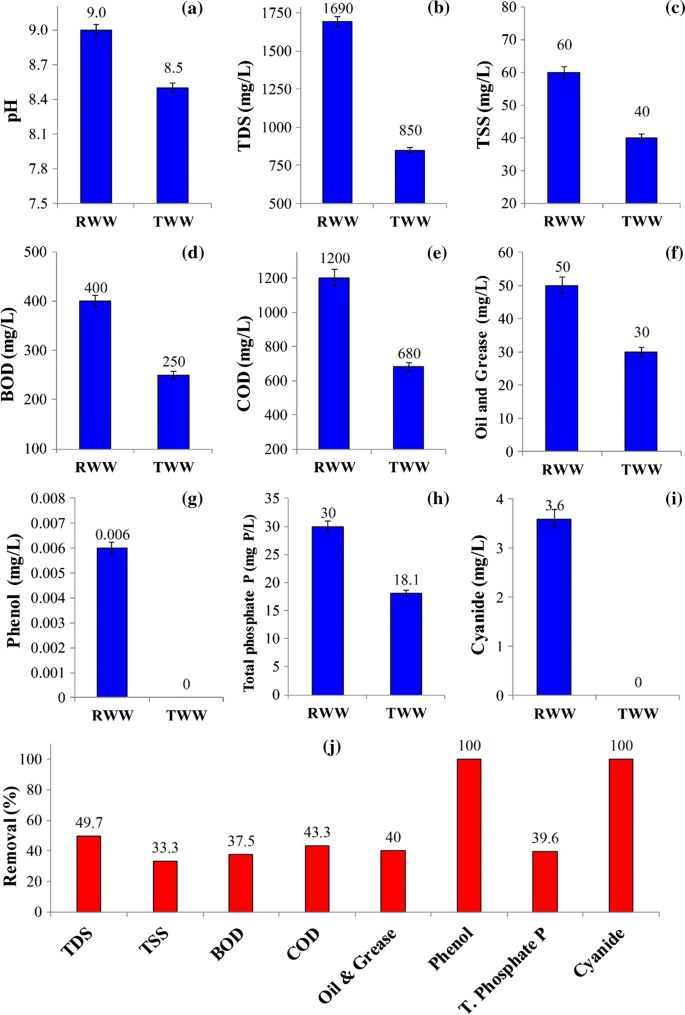

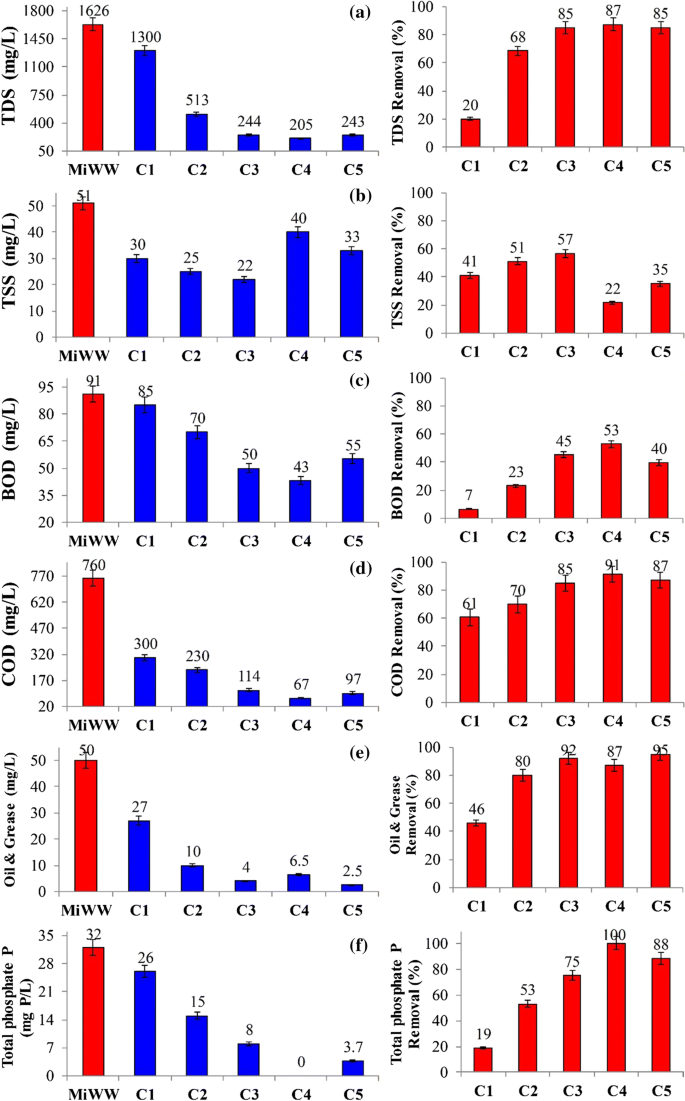

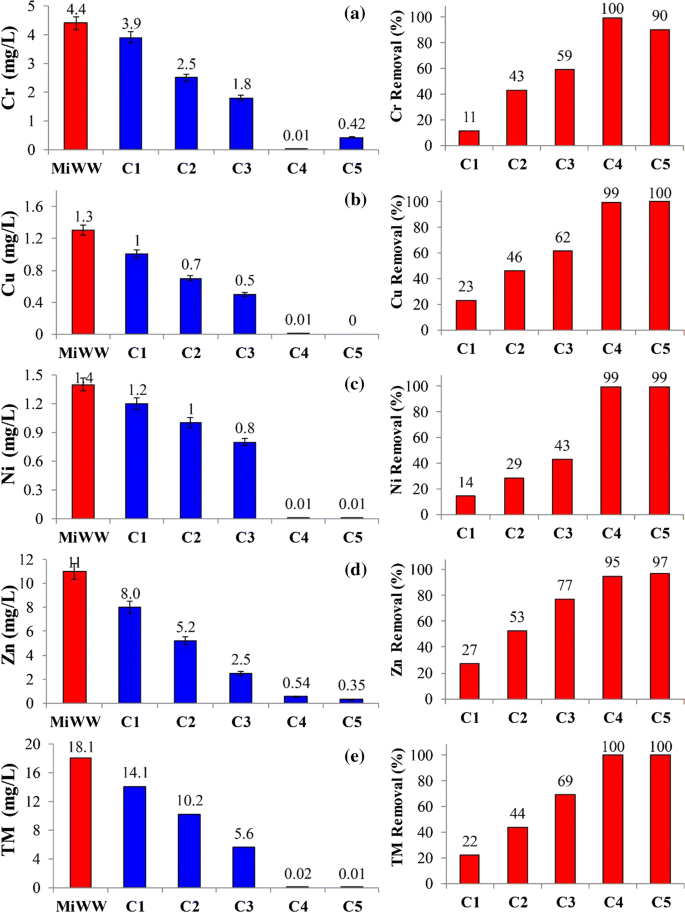

Annonce In a world with ever increasing raw material costs recycling plays an important part. Therefore we investigated the optimal condition of four key parameters namely dissolved oxygen level pH control FeP molar ratio and initial P levels for the maximal recovery of P as valuable products from P-rich industrial wastewater eg electronic industry wastewater effluent using electrochemical process. Maximum adsorption efficiency and recovery of CeIII from electronic industrial effluent using SP- biohydrogel were noted as 884 and 868 which were obtained in column mode at a flow rate of 1 mlmin bed height of 12 cm and 0 dilution.

The detailed procedure and the outcome of this characterization have already been reported in our earlier publication. Our paper attempts to characterize the microbial inhabitants of this niche. Request PDF Recovery of cerium III from electronic industry effluent using novel biohydrogel.

The effluent samples were collected from various discharge areas involving the access sites at the Reverse Osmosis RO unit and the Common Effluent Treatment CET points in the electronic industry located near Hyderabad India. Electronic industry effluent rich in heavy metals and salts is one such ecosystem where diverse heavy metal resistant microbes exist. In the collected effluent cadmium is.

Particular attention was paid to the electrochemical crystallization EC of. Vilokan ADF Solutions recycles 995 pure glycol ready to be mixed into new deicing fluid. The electronics industry especially consumer electronics is an industry whose products include electronic devices such as semiconductors optoelectronics computers digital cameras cell phones and processing equipment.

1397 012022 View the article. Contemporary society uses all manner of electronic devices built in automated or semi-automated factories operated by the industry. The electronics industry generates large amounts of fluoride-containing effluents.

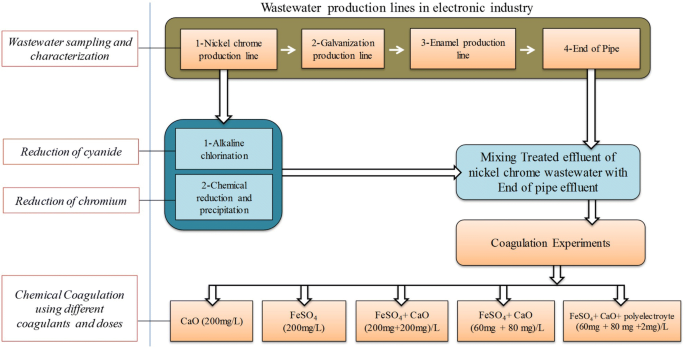

The organisms belonging to this genus has not been exploited as a potential biosorbent for metal. For effluents from the electronics industry may include precipitation coagulation sedimentation sludge dewatering ion exchange filtering membrane purification and separation and neutralization depending on the particular stream. PDF On Dec 1 2019 A Kamari and others published Treatment of electronics industry effluent using low-cost and commercial adsorbents.

The objective of this studyis to study the feasibility of applying reverse osmosis RO membrane separation to reduce fluoride load to less than 1 kgd. Annonce In a world with ever increasing raw material costs recycling plays an important part. Vilokan ADF Solutions recycles 995 pure glycol ready to be mixed into new deicing fluid.

Maximum adsorption efficiency and recovery of CeIII from electronic industrial effluent using SP- biohydrogel were noted as 884 and 868 which were obtained in column mode at a flow rate of 1 mlmin bed height of 12 cm and 0 dilution. A Kamari et al 2019 J. The electronics industry generates large amounts of fluoride-containing effluents.

The electronic industry effluent was characterized to identify the microbial population. Sanitary wastes are treated separately primary and secondary treatment followed by disinfection or disposed. The detailed procedure and the out-come of this characterization have already been reported in our earlier publication 7.

Regeneration studies suggested that SP- biohydrogel could be reused upto 5 cycles and could. Out of the ten strains isolated three strains belonged to the genus Halomonas. The effect of transmembrane pressure on the removal of fluoride ion has been investigated in detail and the design parameters of a small RO separation unit were.

The size of the industry and the use of toxic materials as well as the difficulty of recycling has led to a. A comparative study Find read and cite all the research. A comparative study To cite this article.

Out of the ten strains isolated three strains belonged to the genus Halomonas. Halomonas BVR 1 isolated from an electronic industry effluent had high level of resistance to heavy metals like cadmium lead zinc and to various antibiotics.

Manage Your Industrial Wastewater Suez Group

Wastewater Treatment A Case Study Of Electronics Manufacturing Industry Springerlink

Ppt Electronics Industry Wastewater

Wastewater Treatment A Case Study Of Electronics Manufacturing Industry Springerlink

Electronic Industry Waste Water

Wastewater Treatment A Case Study Of Electronics Manufacturing Industry Springerlink

Industrial Uses Of Water Essential Guide Aquatech

Electronic Industry Waste Water

Electronic Industry Waste Water

Https Www Ifc Org Wps Wcm Connect Ce566b3a 6ba6 46f8 9bd3 531c124fa919 Electronmfg Ppah Pdf Mod Ajperes Cvid Jkd22nt

Aerobic Process Wastewater Treatment Plant Water Treatment Plant Water Treatment

Electronic Industry Waste Water

Flow Diagram Of Effluent Treatment Plant Exide Industries Ltd Download Scientific Diagram

Electronic Industry Waste Water

Example Wastewater Disinfection Control System Control System System Control

Wastewater Treatment A Case Study Of Electronics Manufacturing Industry Springerlink

Take A Look At How Sewage System Works For The Sake Of Cleanliness Call Jw Caruana Fo Wastewater Treatment Plant Sewage Treatment Plant Water Treatment Plant

Wastewater Treatment A Case Study Of Electronics Manufacturing Industry Springerlink

Electronic Industry Waste Water

Post a Comment for "Electronic Industry Effluent"